FORGE

Pressure Equipment

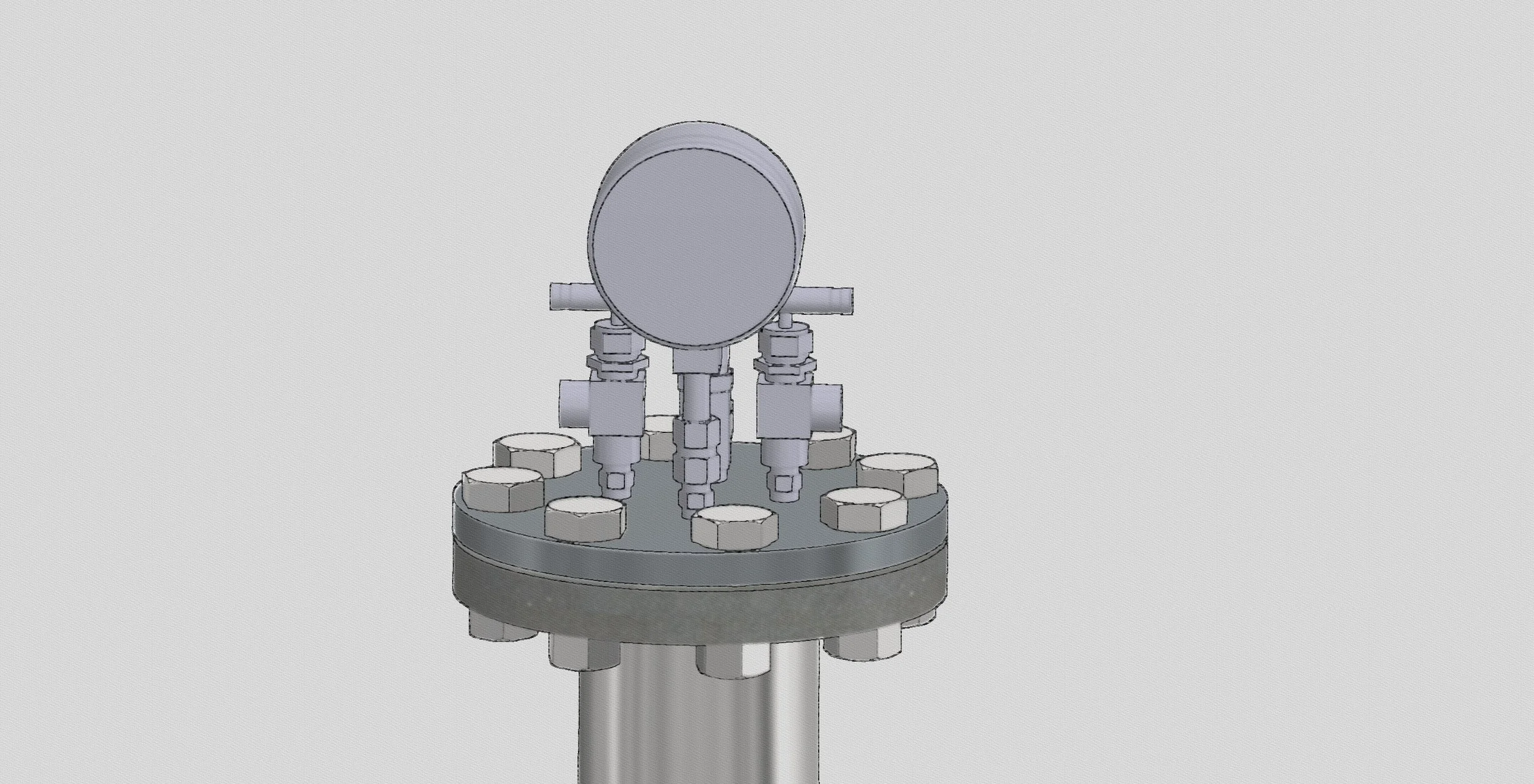

Laboratory Pressure Vessels and Systems

“Forge Pressure Equipment provided exceptional service for our annual reactor servicing — professional, efficient, and reliable from start to finish. Giles made the entire process seamless and stress-free. Highly recommended!”

- CEO, Carbon‑conversion innovation company

Certified Pressure Equipment for Lab & Industry

From off-the-shelf vessels to bespoke high-pressure systems — delivered with full compliance and documentation

New Reactor Systems

Forge Pressure Equipment offers a bespoke pressure vessel design service using ASME design code, and producing vessels and pressure equipment with appropriate CE compliance.

With capability for design and manufacture of laboratory pressure systems ranging from simple non-stirred reactors, to complex PLC controlled tubular reactor systems, Forge Pressure Equipment is ideally placed to serve the needs of the industry.

Our Services

Our comprehensive maintenance and inspection services ensure your pressure vessels remain in peak condition, minimizing downtime and maximizing productivity in your laboratory. Trust Forge Pressure Equipment for timely and precise solutions tailored to meet your equipment’s specific needs.

-

We offer Fitness-for-Service (FFS) assessments in accordance with ASME code guidelines, providing engineering evaluations to determine the structural integrity of components experiencing degradation or damage. Our approach ensures reliable decision-making on continued operation, repair, or replacement—aligned with industry best practices and safety standards.

All vessels tested are returned with a complete test report. -

Our Intermediate service package provides essential maintenance to ensure ongoing performance and safety of your pressure vessels. The service includes a thorough visual inspection to assess general condition and identify any visible signs of wear or damage. Key wear components and consumables, such as O-rings and gaskets, are replaced as standard.

We also carry out rupture disc replacement, and where applicable, perform crack pressure testing of the pressure relief valve to verify correct function. A final pressure test and leak check confirms system integrity before return to service.

Each serviced vessel is supplied with a comprehensive service report, documenting all activities, findings, and replaced components to support traceability and compliance.

Want to tweak this for specific pressure classes, materials, or turnaround timeframes? I'm ready when you are.

-

We provide comprehensive service and refurbishment for intermediate pressure vessels, ensuring continued reliability and regulatory compliance. Each vessel undergoes a systematic disassembly, followed by a thorough cleaning and degreasing process to remove operational residue. A detailed visual inspection identifies any signs of wear, corrosion, or damage.

All wear components and consumables, including O-rings, gaskets, and seals, are replaced with OEM or approved equivalents. The rupture disc is renewed as standard, and, where applicable, the pressure relief valve undergoes a crack pressure test to confirm functional integrity.

Following inspection and part replacement, vessels are reassembled using appropriate anti-seize compounds and PTFE tape on threaded joints, in line with service best practices. A hydrostatic or pneumatic pressure test is performed to validate leak-free performance.

Upon completion, each vessel is returned with a comprehensive service report documenting all actions taken, component replacements, and test outcomes.

-

Our on-site service provides rapid identification and repair of leaks to minimise downtime and maintain operational safety. The process begins with a visual inspection to assess the vessel’s general condition, followed by a pressure test and targeted leak detection, using either customer-supplied gas or FPE-supplied gas (available as a chargeable extra by prior agreement at booking).

Where leaks are identified, repairs are carried out using existing parts wherever possible to reduce cost and lead time. If new components are required, these will be fitted as needed and charged separately, subject to customer approval.

This convenient on-site solution ensures minimal disruption to your process, and each visit concludes with a summary report detailing findings, repairs, and recommendations.

-

Contains all of the testing performed in the intermediate service, while at the customer site.

Pressure tests to be performed using either customer-supplied inert gas or FPE-supplied inert gas (available as a chargeable extra by prior agreement at booking).

Manufactured in the UK

Manufactured in the UK, and using material from European and American mills, Forge Pressure Equipment Ltd is able to offer excellent quality pressure equipment to the research an development community.

About

our company

Forge Pressure Equipment Ltd is involved in the manufacture, service and repair of laboratory pressure vessels.

With experience of a wide variety of laboratory pressure systems, we will be able to help you, whether your needs are supply of a new reaction vessel, maintenance of existing vessels, leak finding or parts replacement.

Contact Us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!